Perfect Place For Best Quality & Innovation

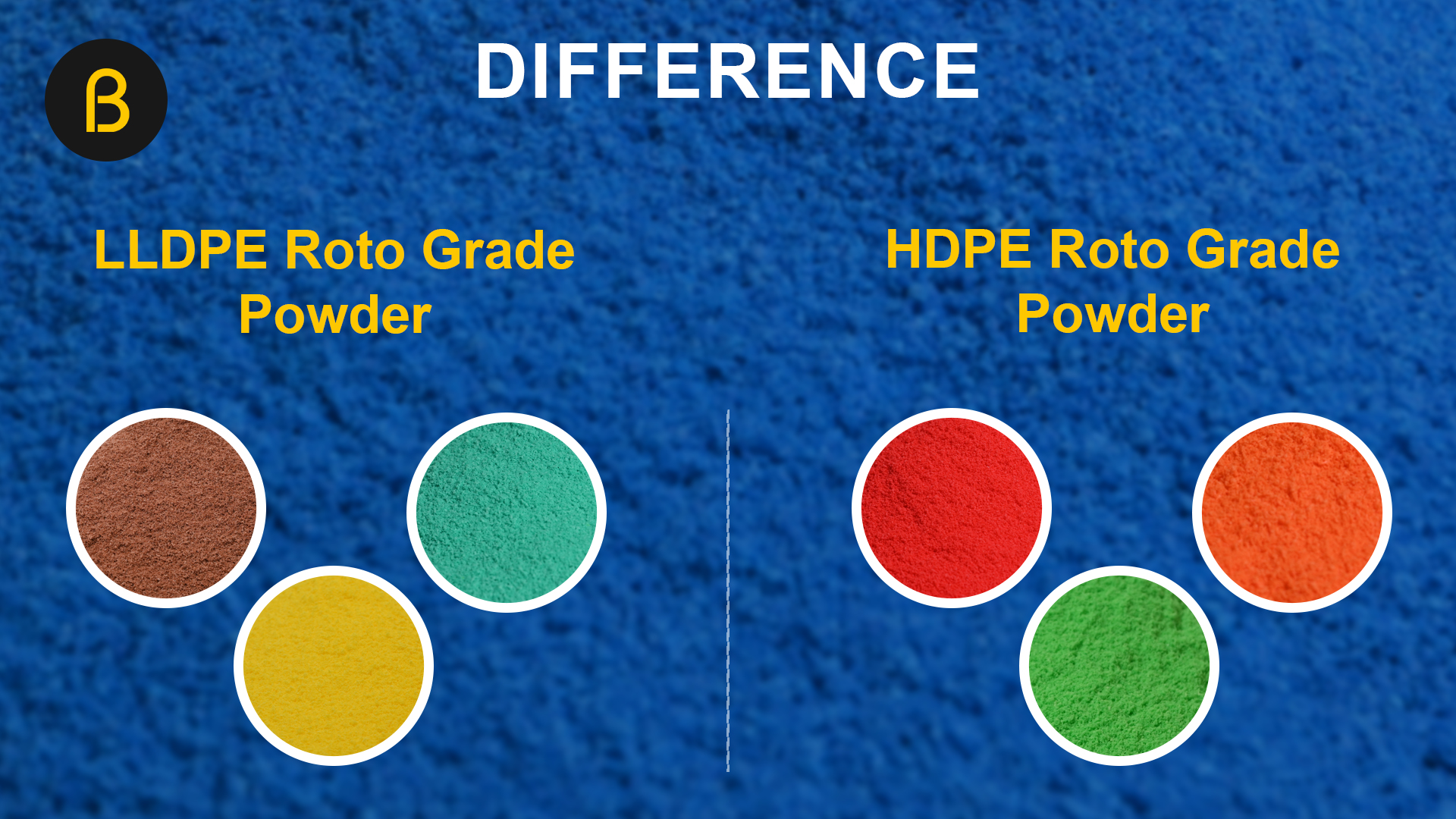

Difference between LLDPE Roto Grade Powder & HDPE Roto Grade Powder.

LLDPE (Linear Low-Density Polyethylene) roto grade powder and HDPE (High-Density Polyethylene) roto grade powder are two different types of plastic materials used in the rotational moulding process. Here are the key differences between LLDPE roto grade powder and HDPE roto grade powder:

Molecular Structure

The molecular structure of LLDPE and HDPE differs, leading to distinct material properties. LLDPE has a linear and branched structure with short chains, while HDPE has a linear structure with long, closely packed chains. This structural difference influences their physical and mechanical properties.

Flexibility and Impact Resistance

LLDPE generally offers higher flexibility and better impact resistance compared to HDPE. Its short-chain branching provides more mobility between polymer chains, allowing for greater flexibility and impact resistance. HDPE, on the other hand, is stiffer and has lower impact resistance.

Melt Flow Rate

LLDPE typically has a higher melt flow rate (MFR) than HDPE. MFR refers to the ease with which a polymer melts and flows during the moulding process. A higher MFR indicates that LLDPE has better flow characteristics, allowing for easier mould filling and improved part quality in intricate or complex designs.

Density

HDPE has a higher density than LLDPE. The higher density contributes to HDPE's stiffness and rigidity compared to LLDPE. LLDPE's lower density provides it with greater flexibility and improved impact resistance.

Environmental Stress Crack Resistance

LLDPE generally exhibits higher environmental stress crack resistance (ESCR) than HDPE. ESCR refers to a material's ability to resist cracking when exposed to stress, such as chemicals or environmental factors. LLDPE's short-chain branching structure enhances its resistance to environmental stress cracking.

UV Resistance

LLDPE typically offers better UV resistance compared to HDPE. The short-chain branching in LLDPE helps to absorb and dissipate UV radiation, providing improved protection against degradation caused by sunlight exposure. HDPE may require additives or special formulations to enhance its UV resistance.

Applications

LLDPE roto grade powder is often preferred for applications that require flexibility, impact resistance, and excellent mouldability. It is commonly used for manufacturing products like water tanks, playground equipment, storage containers, and automotive parts. HDPE roto grade powder, with its higher stiffness and rigidity, is suitable for applications requiring structural strength, such as large industrial tanks, outdoor furniture, agricultural equipment, and marine components.

When selecting between LLDPE and HDPE roto grade powders, consider the specific requirements of your application, including desired flexibility, impact resistance, UV stability, and stiffness. It is recommended to consult with material suppliers or industry experts to ensure the chosen material aligns with your product’s needs.